Practical and cost-effective industrial tents

TEMPORARY WAREHOUSE = TENT HALL = WHOLE YEAR FULLY FUNCTIONAL WAREHOUSE

industrial tent = mobile industrial hall

Impenetrable, durable, stable, tested in all weather conditions, even as extreme as those prevailing on Spitsbergen. If you are not afraid of using modern, innovative solutions that will help you save time and considerably increase the mobility of your business, then industrial tents are designed for you.

One tent, multiple functions

Industrial tents are not only temporary warehouses with a light, solid and durable construction. They are also buildings that may successfully serve various other functions. They may be used as logistics centres, industrial halls, car washes, paint shops, waste sorting stations, stables and horse riding halls, as well as various sports facilities such as tennis courts, ice rinks, swimming pools or portable locker rooms.

Industrial tents in agriculture

Industrial tents are broadly used in agriculture. They can serve as livestock buildings (cowsheds, poultry houses, pig houses), temporary barns, storage hall for crops (in cold room conditions), buildings for sorting vegetables and fruits, as well as a safe warehouse for agricultural equipment. Their construction does not require the use of any internal ropes and as such the entire volume may be used for your business activity.

Industrial tents in agriculture

Industrial tents are broadly used in agriculture. They can serve as livestock buildings (cowsheds, poultry houses, pig houses), temporary barns, storage hall for crops (in cold room conditions), buildings for sorting vegetables and fruits, as well as a safe warehouse for agricultural equipment. Their construction does not require the use of any internal ropes and as such the entire volume may be used for your business activity.

Additional facilities

Industrial tents we offer on request may be equipped with additional solutions and conveniences, tailored to the customer. These include, among others, heating, lighting, protection against condensation, partly or fully transparent roof that provides access to natural light, steel doors, as well as a pneumatic roof that provides additional insulation.

Industrial tents can be used for production with low requirements in terms of thermal conditions:

- production and large-scale painting processes (shipyards), grinding of steel elements

- food sorting

- car washing services

- waste sorting

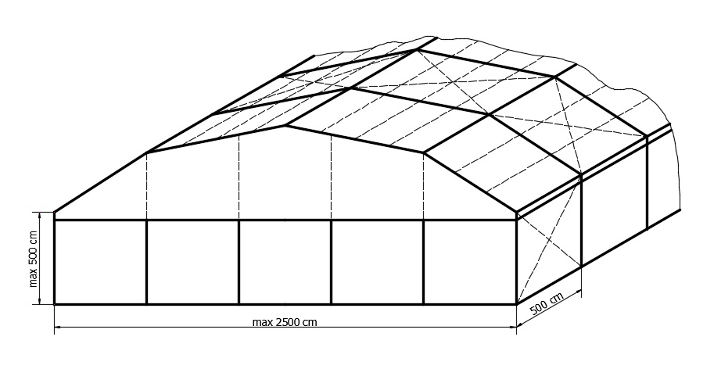

Tent halls do not require solid fundaments and are capable to meet every expectation for industrial halls or warehouses in terms of functionality. Pol-Plan offers mobile tent halls, which may also be placed on tracks (shipyards). he storage halls are erected based on innovative constructions from anodized aluminum, which guarantees durability and safety (snow load of 150 - 300 kg/m²), ease of installation and diversity of usage.

Due to rapid installation (even 1 – 2 days) and durability (minimum of 10 years) the storage halls based on tent halls are a financially-attractive investment.

The costs of an industrial tent is equal to approx. 25% of the costs of a traditional industrial hall.

Industrial hall with gantry crane

The construction of an industrial hall in traditional technology is associated with considerable investment outlays and time. The solution is a production hall built based on the technology of tent halls. The lightweight and durable construction made of aluminum profiles can be adapted to local wind and snow loads.

In this technology, an insulated production hall with dimensions of 25x100x4.5 m was created for the company Butrans from Poznań, in which various types of precast concrete products are manufactured. A unique feature of this temporary production hall which in fact is permament is a gantry crane with a lifting capacity of up to 5 tons working along the entire length of the industrial hall.

Industrial tent – a production hall for a trailer manufacturer.

Among the industrial tents built by us we can highlight a production hall for the Polish company Gniotpol. When assessing its needs in terms of production space, the company's management came to the conclusion that it would be necessary to invest in a new hall for the assembly of trailer components.

In view of the market requirements, and the increased demand for trailers, it was essential to build a new hall and organise production as quickly as possible.

After a detailed analysis of the requirements of the production process and a comparison of tenders, the company opted for an industrial tent from Pol-Plan. The production process does not require a highly insulated hall. Therefore there was no need to use high-cost side units made of sandwich panels and trapezoidal sheets. The covering of the entire hall would be in resistant PVC of the highest quality. Throughout the entire length of one side of the hall, the customer wanted sliding gates with large windows, which facilitates the delivery of components to the production stations, and ensures natural lighting.

An industrial PVC tent does not provide sufficient insulation for traditional heating systems. Therefore, radiant heaters were used, which do not heat the air inside the hall, but have a direct effect on the employees, which ensures the required working comfort.

Insulated industrial hall

An insulated production hall can be built in a few days and it will be a fully functional industrial facility designed for 50 years of use. This type of insulated production hall (24x30x4,5 m) with sandwich panel wall sheeting and a pumped roof was created for the Polish company Mark John, which produces spare parts for the automotive, agricultural and machine industries. Specialized CNC machines work in the hall equipped with 12 polyurethane windows.

produktion hall for the Les Yachts de Lyon shipyard

Shipyards, producing sea and inland yachts have significant needs in terms of a covered production area. A traditionally built production hall with a large area is an expensive and time-consuming investment. The problem can be solved by long-term tent halls with a span of up to 60m, which are built in a few days and do not require permanent foundations. Sometimes, however, a smaller hangar is enough to protect work on a single unit, which, if necessary, can be extended with further segments or easily disassembled and moved to another location. This solution was chosen by the French shipyard Les Yachts de Lyon, which produces luxury sea and inland yachts.

MATERIALS

TENT HALLS WITH A CASING BASED ON TRAPEZOIDAL SHEETS

TENT HALLS WITH A CASING BASED ON SANDWICH PANELS (WITH FOAM OR STYROFOAM)

PVC-BASED ROOFING

PVC-BASED ROOFING WITH A HEADLINING

PUMPED ROOF

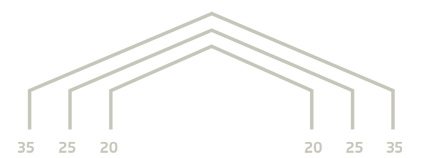

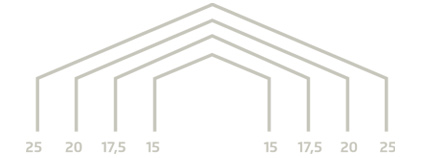

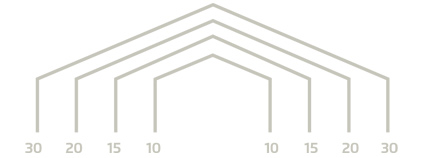

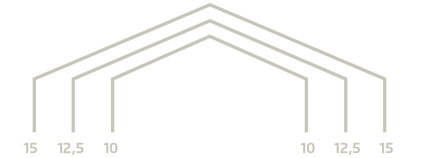

INDUSTRIAL TENT HALLS - AVAILABLE SIZES

INDUSTRIAL TENTS „MADE-TO-MEASURE”

INDUSTRIAL HALLS PRICES

-

Sale!Temporary warehouse (storage tent) 15x40x4,5m, sandwich panel, with polyurethane core PUR, t = 60

INDUSTRIAL TENTS - PORTFOLIO

1600 TENT HALLS ANNUALLY

Industrial tent. Quality, stability of construction, safety

Attention to details, proven design solutions, guaranteed durability and stability of construction of the tent hall – without any support and internal lines – allows to use the full volume of the hall.

Pumped roof increases the thermal isolation of the hall and facilitates the removal of snow.

FUNCTIONALITY – VERSATILITY OF USE

STORAGE HALLS – LOGISTIC CENTRES

INDUSTRIAL HALLS

PAINTSHOPS

CARWASH

WASTE SORTING PLANTS

PIGPENS – COWSHEDS – HEN HOUSES – CHAMPIGNON STORING HALLS – FRUIT SORTING PLANTS

STABLES – HORSE RIDING FACILITIES

SPORT HALLS – TENNIS COURTS – ICE RINKS

building, industry, logistics, automotives, trade, agriculture

WHY TENT HALLS?

- COST-EFFECTIVE ALTERNATIVE TO HEAVY BUILDINGS

- MOBILITY, FAST INSTALLATION AND REMOVAL (1 TO 2 DAYS)

- DURABILITY - MINIMUM 10 years

- RESISTANCE TO EXTREME WEATHER CONDITIONS - WIND, SNOW, HAIL, RAIN

- TAILORED SOLUTIONS (INSULATED WALL PANELS, ENTRANCE GATE, WINDOWS AND DOORS, PUMPED ROOF)

We were trusted by:

WE WORK GLOBALLY

The quality of our tent halls is appreciated by clients all over the world.

SPITSBERGEN, OMAN, NORWAY, SAUDI ARABIA, RUSSIA, GREECE, FRANCE, GERMANY, GREAT BRITAN, SPAIN, HOLLAND, ITALY

THE QUALITY OF OUR PRODUCTS IS ATTESTED BY THE FOLLOWING STANDARDS AND CERTIFICATES:

POL-PLAN Sp. z o.o.

ul. Wrocławska 42/44, 62-060 Stęszew / Zamysłowo

REGISTERED CAPITAL: 5 800 000,- PLN – paid in full