AGRICULTURAL HALLS

COWSHEDS

PIGPENS

HEN HOUSES

COLD STORAGE, FRUIT AND VEGETABLE SORTING HALLS

TEMPORARY BARNS CROP WAREHOUSES

TEMPORARY BARNS

Temporary barns, agricultural halls, also abbreviated as agrohalls, are our specialty – we are capable of creating this type of atypical objects for our Clients on request. They are mainly designed for storage of agricultural crops under roofing, they may also protect agricultural equipments against weather conditions (temporary garages).

Specific needs associated with livestock breeding or storing specific agricultural crops influence the design assumptions of the agricultural storage hall and additional equipment. In case of halls, which should function as cowsheds, stables, hen houses or pigpens, the welfare of animals is the most crucial factor determining the size of the agricultural hall and types of ventilation, heating and lighting systems. The construction of the hall is also influenced by the required parameters of watering holes and feeders.

Pol-Plan offers agricultural halls which cover the entire spectrum of possible applications in agriculture:

- livestock buildings (cowsheds, hen houses, pigpens)

- temporary barns, crop storage halls (cold storage and freezing)

- fruit and vegetable sorting halls

- warehouses for agricultural equipment

- temporary garages

Temporary barns based on aluminum construction fully meet the criteria of and additionally are a cost-effective alternative for traditional, “heavy” building technologies. They are easy to install and may also be used seasonally, due to the fact that their time of assembly and disassembly usually takes approx. one day. The agrohalls offered by Pol-Plan are highest quality tent halls for the most demanding Customers.

MATERIALS

TEMPORARY BARNS WITH A CASING BASED ON TRAPEZOIDAL SHEETS

TEMPORARY BARNS WITH A CASING BASED ON SANDWICH PANELS (WITH FOAM OR STYROFOAM)

PVC-BASED ROOFING

PVC-BASED ROOFING WITH A HEADLINING

PUMPED ROOF

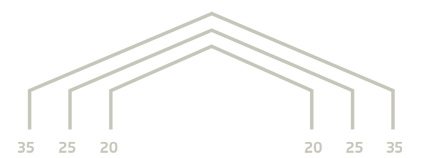

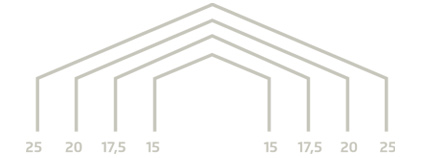

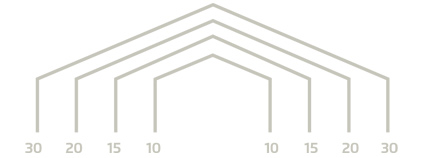

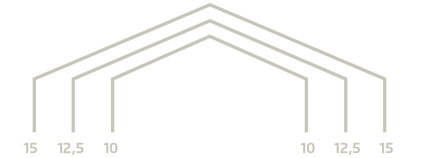

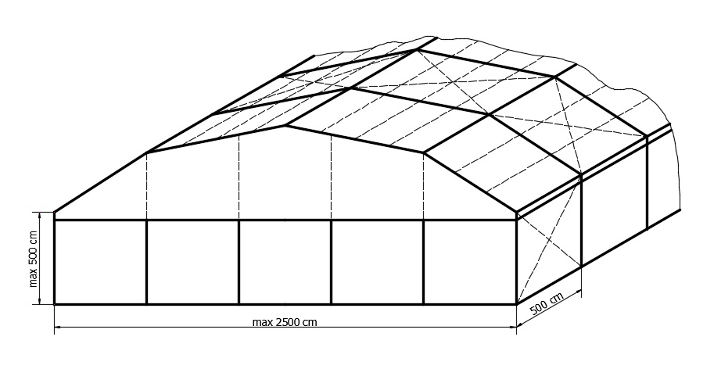

TENT HALLS - AVAILABLE SIZES

TEMPORARY BARNS „MADE-TO-MEASURE”

TENT HALLS - PORTFOLIO

1600 TENT HALLS ANNUALLY

Quality, stability of construction, safety

Attention to details, proven design solutions, guaranteed durability and stability of construction of the tent hall – without any support and internal lines – allows to use the full volume of the hall.

Pumped roof increases the thermal isolation of the hall and facilitates the removal of snow.

FUNCTIONALITY – VERSATILITY OF USE

STORAGE HALLS – LOGISTIC CENTRES

INDUSTRIAL HALLS

PAINTSHOPS

CARWASH

WASTE SORTING PLANTS

TEMPORARY BARNS

PIGPENS – COWSHEDS – HEN HOUSES – CHAMPIGNON STORING HALLS – FRUIT SORTING PLANTS

STABLES – HORSE RIDING FACILITIES

SPORT HALLS – TENNIS COURTS – ICE RINKS

building, industry, logistics, automotives, trade, agriculture

WHY TENT HALLS?

- COST-EFFECTIVE ALTERNATIVE TO HEAVY BUILDINGS

- MOBILITY, FAST INSTALLATION AND REMOVAL (1 TO 2 DAYS)

- DURABILITY - MINIMUM 10 years

- RESISTANCE TO EXTREME WEATHER CONDITIONS - WIND, SNOW, HAIL, RAIN

- TAILORED SOLUTIONS (INSULATED WALL PANELS, ENTRANCE GATE, WINDOWS AND DOORS, PUMPED ROOF)

We were trusted by:

WE WORK GLOBALLY

The quality of our tent halls is appreciated by clients all over the world.

SPITSBERGEN, OMAN, NORWAY, SAUDI ARABIA, RUSSIA, GREECE, FRANCE, GERMANY, GREAT BRITAN, SPAIN, HOLLAND, ITALY

THE QUALITY OF OUR PRODUCTS IS ATTESTED BY THE FOLLOWING STANDARDS AND CERTIFICATES:

POL-PLAN Sp. z o.o.

ul. Wrocławska 42/44, 62-060 Stęszew / Zamysłowo

REGISTERED CAPITAL: 5 800 000,- PLN – paid in full